QR Code

Products

- Conductor Pulley Stringing Blocks

- Transmission Line Stringing Tools

- Overhead Line Stringing Equipment

- Anti-Twisting Steel Wire Rope

- Transmission Line Pulling Winches

- Tower Erection Tools Gin Pole

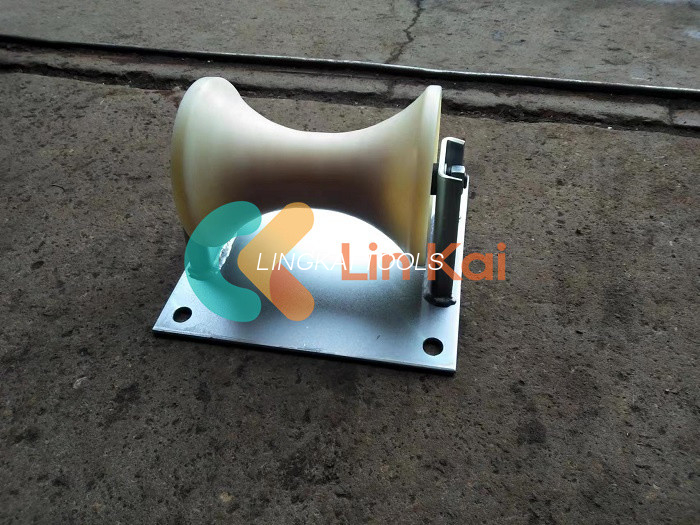

- Underground cable Installation Tools

- Hydraulic Tools

- Electrical Cable Pulling Tools

- Conductor Stringing Blocks

- Transmission Stringing Blocks